Lubricants > All Lubricants and Services > Greases

Greases

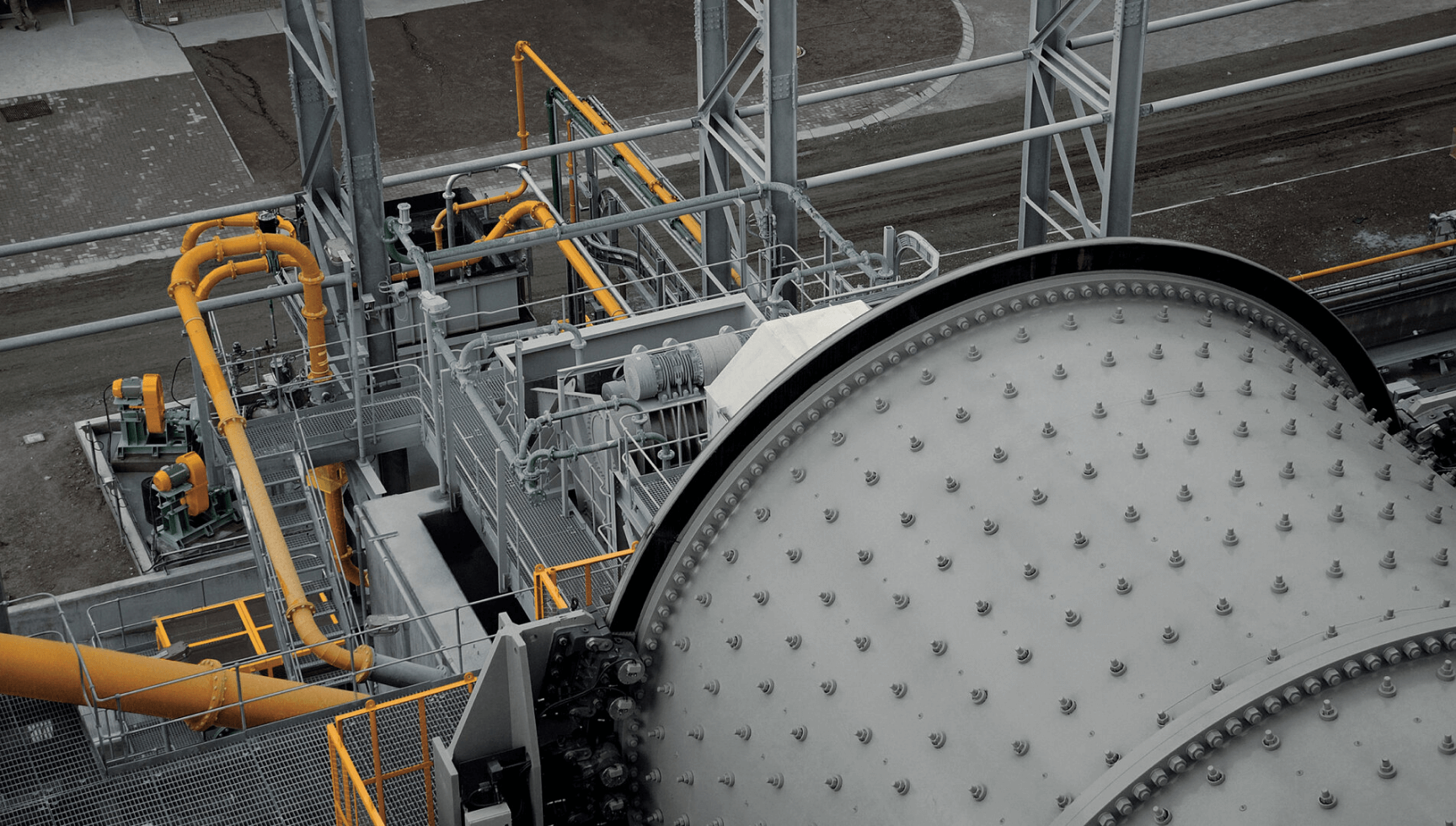

Sustainably resolving wear and corrosion

with the optimal grease choice.

High-quality lubricating greases for optimal grease lubrication, to help you keep your production up and running and your machines in good condition.

Wear and corrosion can obstruct your production process and damage your machinery. Lubricating greases from Klüber Lubrication will help keep excellent solutions for mechanical friction. Klüber lubricating greases are effective and offer sustained protection against wear, corrosion and risks from external factors.

Our proven track record for individual requirements include applications for speciality lubricants applied on valves and fittings, rolling and plain bearings, gears, plastics, contacts, pneumatic components and many more.

Our proven track record for individual requirements include applications for speciality lubricants applied on valves and fittings, rolling and plain bearings, gears, plastics, contacts, pneumatic components and many more.

Officially representing

Klüber Lubrications

a world market leader.

For high-quality solutions, competence and expertise based on more than 90 years of research and experience.

Protect your machines against wear and corrosion. Be on the safe side, mechanically and economically.

The design and mode of operation of your machine will determine which lubricant is right for you.

The right lubricant will help you master existing challenges and avoid new ones.

Lubricating greases are the ideal choice when you want to provide long-term protection for friction points.

aprox.

75%

lubricating oil

aprox.

15%

thickener

up to

10% additives

Grease lubrications VS Oil/Fluid lubrications

Grease lubrications are consistent and stay longer at the friction point.

Problems requiring grease lubrication:

- lubrication points that are not sealed and the base oil is held at the friction point by the consistency of the lubricating grease

- points where relubrication is not possible

Advantages of grease lubrication:

- Simpler design with respect to sealing

- Long service life with reduced maintenance effort

- Often a lifetime lubrication

- Lower consumption

- Improved sealing

- enables an optimal supply of the base oil to the friction point;

- a single lubricant fill will be able to provide lubricity over the component’s entire lifetime

Examples

for grease applications:

- spindle bearings in machine tools, which rotate very fast and have low surface pressure

for oil or fluid applications:

- large drives with high surface pressures and low speed

ROI with optimal grease lubrication

Boost your production to a new level with our product range which includes more than 1,500 different lubricating greases to precisely match your individual needs. Get covered with high-performance lubricating greases for unusually high or low temperatures, and especially versatile lubricating greases.

For reliable operation and service life attainment of rolling bearings a suitable grease lubrication is indispensable. From high-temperature, low-temperature, high-speed or heavy-duty lubricating greases, as well as H1 lubricating greases, we will offer the suitable lubricant which meets your individual demands.

We offer

greases for

Rolling bearings

and plain bearings

and plain bearings

Gears

Plastics

Electrical

contacts

contacts

Industrial valves

and actuators

and actuators

Pneumatic

systems

systems